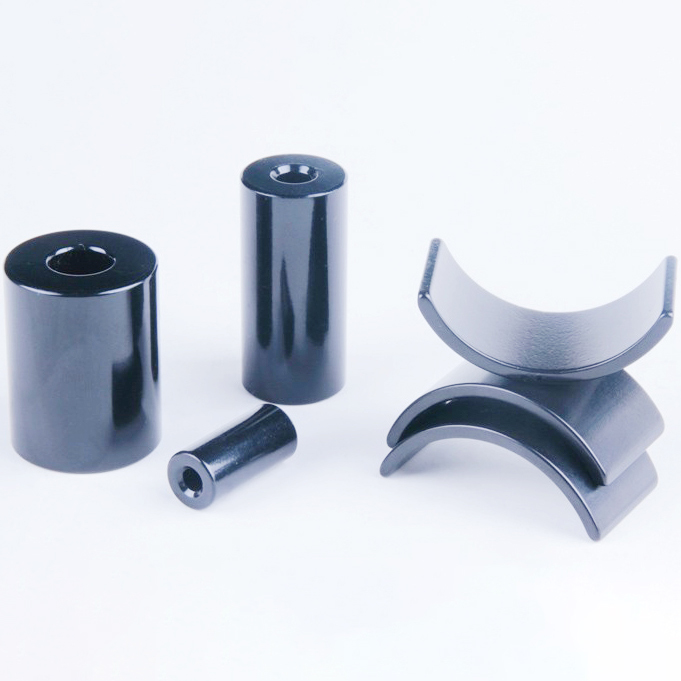

Alaabta OEM/ODM Shiinaha Siintered Silinder Joogta ah NdFeB Magnet

Waxaan si joogto ah u fulinaa ruuxeena "hal-abuur keenaya horumar, tayo sare leh samaynta nolol-maalmeedka qaarkood, Xayeysiinta Maareynta iyo faa'iidada suuqgeynta, Dhibcaha credit soo jiidashada iibsada OEM/ODM Supplier China Sintered Joogtada ah Sylinder NdFeBMagnetShirkaddayadu waxay u heellan tahay "macmiilka marka hore" waxayna ka go'an tahay inay ka caawiso macaamiisha inay ballaariyaan ganacsigooda, si ay u noqdaan Boss-ka Weyn!

Waxaan si joogto ah u fulinaa ruuxeena “Innovation keenaya horumar, tayo sare leh samaynta nolol maalmeedka, Xayeysiinta maamulka iyo faa'iidada suuqgeynta, dhibcaha credit soo jiidashada iibsadayaashaShiinaha Neodymium Magnet,Magnet , Hadafka xiga waa in aan dhaafno waxa laga filayo macmiil kasta anagoo siinaya adeeg macmiisha oo heersare ah, dabacsanaan korodhay iyo qiimo weyn. Dhammaan, macaamiishayada la'aanteed ma jirno; la'aanteed macaamiil faraxsan oo si buuxda u qanacsan, waan ku guuldareysanay. Waxaan raadineynaa jumlada, markab tuur. Fadlan nala soo xiriir haddii aad xiiso u leedahay alaabtayada. Waxaan rajeyneynaa inaan ganacsi la samayno dhammaantiin. Tayo sare leh iyo shixnad degdeg ah!

Hordhac:

Neodymium magnets (NdFeB) - Magnet dhul dhif ah oo joogto ah oo ka kooban neodymium, birta iyo boron, Shiinuhu wuxuu bilaabay macdantan gudaha 1980-yadii. Magnet-ka NeFeB waa la isku riixay oo lagu dhex qooyay jawi ilaalin ah. Haddii hababka aan si fiican loo koontaroolin, waxay u horseedi doontaa cillad tayo leh sababtoo ah daxalka. Waqtiga SURTIME, waxaan ka saareynaa dhibaatooyinkan isla bilawgii anagoo sidnay kontaroolo tayada waxaanan u aragnaa inay tahay qayb lama huraan ah, maaha oo kaliya alaabta dhamaadka laakiin sidoo kale inta lagu jiro geedi socodka muhiimka ah ee goobta.

Faa'iidada:

Astaamaha magnet-yadani aad ayey uga sarreeyaan kuwa dhaqameedka waxayna hadda yihiin kuwa ugu awoodda badan codsiga. Qasabkooda sare iyo joogitaanka sare waxay u oggolaanayaan naqshadeynta cusub iyo suurtagalnimada kordhinta goobta magnetic codsiga halkaasoo boosku xaddidan yahay ama meesha loo baahan yahay garoon xoog leh. Magnets NdFeB waxay aad ugu nugul yihiin daxalka. Sidaa darteed u baahan dahaarka dusha ka ilaalinaya. Isticmaalka magnetka NdFeB waxaa lagu shardiyaa heerkul aad u ballaaran oo ka socda 80ºC ilaa 230ºC. Iyo sidoo kale waxay ku shaqeysaa heerkul ka hooseeya 0 ℃.

Codsiga:

Neodymium magnets waxaa loo isticmaalaa noocyo kala duwan oo lenses magnetic si diiradda loo saaro, leexinta walxaha la dallacay ee elektiroonigga ah, nidaamyada biriiga, dareeraha, dareeraha, nidaamka magnetic ee rotor iyo micro matoorada, iyo goobta sayniska, daawada (tomography, NMR spectrometers), iwm.

Maanta, magnets NdFeB ayaa si aad ah looga isticmaalaa adduunka oo dhan. Horumarinta walxahan weli ma dhammaystirna; Joogitaanka iyo xoogga xoogga garoonka ayaa si joogto ah loo kordhinayaa. Tamarta sare ee magnets-ka ndFeB waxay la macno tahay in matoorada iyo dareemayaasha la dhisi karo weligood ka sii yaraan - tani waxay muujinaysaa korodhka hufnaanta waxqabadka. Horumarka socda ayaa sahlaya in walxahan xiisaha leh si joogto ah loogu soo bandhigo meelo cusub. Dhammaan qiimayaasha la sheegay waxaa lagu go'aamiyay iyadoo la adeegsanayo muunado caadi ah iyadoo loo eegayo IEC 60404-5. Tilmaamaha soo socdaa waxay u adeegaan sida qiyamka tixraaca waana kala duwanaan karaan. Wixii macluumaad dheeraad ah fadlan la xidhiidh injineeradayada codsiga.

| Sintered NdFeBMagnetGuryaha Jirka | ||||||||

| Darajo | Joogista | Rev. Temp.- Coeff. Ee Br | Xoog ku Qasab ah | Xoogaga qasabka ah ee gudaha | Rev. Temp.- Coeff. ee Hcj | Max. Alaabta Tamarta | Max. Heerkulka shaqada | Cufnaanta |

| Br (KGs) | Hcb (Adiga) | Hcj (Adiga) | (BH) ugu badnaan. (MGOe) | g/cm³ | ||||

| N35 | 11.7-12.2 | -0.11~-0.12 | ≥10.9 | ≥12 | -0.58~-0.78 | 33-36 | 80℃ | 7.6 |

| N38 | 12.2-12.5 | -0.11~-0.12 | ≥11.3 | ≥12 | -0.58~-0.78 | 36-39 | 80℃ | 7.6 |

| N40 | 12.5-12.8 | -0.11~-0.12 | ≥11.5 | ≥12 | -0.58~-0.78 | 38-41 | 80℃ | 7.6 |

| N42 | 12.8-13.2 | -0.11~-0.12 | ≥11.5 | ≥12 | -0.58~-0.78 | 40-43 | 80℃ | 7.6 |

| N45 | 13.2-13.8 | -0.11~-0.12 | ≥11.6 | ≥12 | -0.58~-0.78 | 43-46 | 80℃ | 7.6 |

| N48 | 13.8-14.2 | -0.11~-0.12 | ≥11.6 | ≥12 | -0.58~-0.78 | 46-49 | 80℃ | 7.6 |

| N50 | 14.0-14.5 | -0.11~-0.12 | ≥10.0 | ≥12 | -0.58~-0.78 | 48-51 | 80℃ | 7.6 |

| N52 | 14.3-14.8 | -0.11~-0.12 | ≥10.0 | ≥12 | -0.58~-0.78 | 50-53 | 80℃ | 7.6 |

| N33M | 11.3-11.7 | -0.11~-0.12 | ≥10.5 | ≥14 | -0.58~-0.72 | 31-33 | 100 ℃ | 7.6 |

| N35M | 11.7-12.2 | -0.11~-0.12 | ≥10.9 | ≥14 | -0.58~-0.72 | 33-36 | 100 ℃ | 7.6 |

| N38M | 12.2-12.5 | -0.11~-0.12 | ≥11.3 | ≥14 | -0.58~-0.72 | 36-39 | 100 ℃ | 7.6 |

| N40M | 12.5-12.8 | -0.11~-0.12 | ≥11.6 | ≥14 | -0.58~-0.72 | 38-41 | 100 ℃ | 7.6 |

| N42M | 12.8-13.2 | -0.11~-0.12 | ≥12.0 | ≥14 | -0.58~-0.72 | 40-43 | 100 ℃ | 7.6 |

| N45M | 13.2-13.8 | -0.11~-0.12 | ≥12.5 | ≥14 | -0.58~-0.72 | 43-46 | 100 ℃ | 7.6 |

| N48M | 13.6-14.3 | -0.11~-0.12 | ≥12.9 | ≥14 | -0.58~-0.72 | 46-49 | 100 ℃ | 7.6 |

| N50M | 14.0-14.5 | -0.11~-0.12 | ≥13.0 | ≥14 | -0.58~-0.72 | 48-51 | 100 ℃ | 7.6 |

| N35H | 11.7-12.2 | -0.11~-0.12 | ≥10.9 | ≥17 | -0.58~-0.70 | 33-36 | 120℃ | 7.6 |

| N38H | 12.2-12.5 | -0.11~-0.12 | ≥11.3 | ≥17 | -0.58~-0.70 | 36-39 | 120℃ | 7.6 |

| N40H | 12.5-12.8 | -0.11~-0.12 | ≥11.6 | ≥17 | -0.58~-0.70 | 38-41 | 120℃ | 7.6 |

| N42H | 12.8-13.2 | -0.11~-0.12 | ≥12.0 | ≥17 | -0.58~-0.70 | 40-43 | 120℃ | 7.6 |

| N45H | 13.2-13.6 | -0.11~-0.12 | ≥12.1 | ≥17 | -0.58~-0.70 | 43-46 | 120℃ | 7.6 |

| N48H | 13.7-14.3 | -0.11~-0.12 | ≥12.5 | ≥17 | -0.58~-0.70 | 46-49 | 120℃ | 7.6 |

| N35SH | 11.7-12.2 | -0.11~-0.12 | ≥11.0 | ≥20 | -0.56~-0.70 | 33-36 | 150 ℃ | 7.6 |

| N38SH | 12.2-12.5 | -0.11~-0.12 | ≥11.4 | ≥20 | -0.56~-0.70 | 36-39 | 150 ℃ | 7.6 |

| N40SH | 12.5-12.8 | -0.11~-0.12 | ≥11.8 | ≥20 | -0.56~-0.70 | 38-41 | 150 ℃ | 7.6 |

| N42SH | 12.8-13.2 | -0.11~-0.12 | ≥12.4 | ≥20 | -0.56~-0.70 | 40-43 | 150 ℃ | 7.6 |

| N45SH | 13.2-13.8 | -0.11~-0.12 | ≥12.6 | ≥20 | -0.56~-0.70 | 43-46 | 150 ℃ | 7.6 |

| N28UH | 10.2-10.8 | -0.11~-0.12 | ≥9.6 | ≥25 | -0.52~-0.70 | 26-29 | 180℃ | 7.6 |

| N30UH | 10.8-11.3 | -0.11~-0.12 | ≥10.2 | ≥25 | -0.52~-0.70 | 28-31 | 180℃ | 7.6 |

| N33UH | 11.3-11.7 | -0.11~-0.12 | ≥10.7 | ≥25 | -0.52~-0.70 | 31-34 | 180℃ | 7.6 |

| N35UH | 11.8-12.2 | -0.11~-0.12 | ≥10.8 | ≥25 | -0.52~-0.70 | 33-36 | 180℃ | 7.6 |

| N38UH | 12.2-12.5 | -0.11~-0.12 | ≥11.0 | ≥25 | -0.52~-0.70 | 36-39 | 180℃ | 7.6 |

| N40UH | 12.5-12.8 | -0.11~-0.12 | ≥11.3 | ≥25 | -0.52~-0.70 | 38-41 | 180℃ | 7.6 |

| N28EH | 10.4-10.9 | -0.105~-0.120 | ≥9.8 | ≥30 | -0.48~-0.70 | 26-29 | 200℃ | 7.6 |

| N30EH | 10.8-11.3 | -0.105~-0.120 | ≥10.2 | ≥30 | -0.48~-0.70 | 28-31 | 200℃ | 7.6 |

| N33EH | 11.3-11.7 | -0.105~-0.120 | ≥10.5 | ≥30 | -0.48~-0.70 | 31-34 | 200℃ | 7.6 |

| N35EH | 11.7-12.2 | -0.105~-0.120 | ≥11.0 | ≥30 | -0.48~-0.70 | 33-36 | 200℃ | 7.6 |

| N38EH | 12.2-12.5 | -0.105~-0.120 | ≥11.3 | ≥30 | -0.48~-0.70 | 36-39 | 200℃ | 7.6 |

| N28AH | 10.4-10.9 | -0.105~-0.120 | ≥9.9 | ≥33 | -0.45~-0.70 | 26-29 | 230℃ | 7.6 |

| N30AH | 10.8-11.3 | -0.105~-0.120 | ≥10.3 | ≥33 | -0.45~-0.70 | 28-31 | 230℃ | 7.6 |

| N33AH | 11.3-11.7 | -0.105~-0.120 | ≥10.6 | ≥33 | -0.45~-0.70 | 31-34 | 230℃ | 7.6 |

| Fiiro gaar ah: | ||||||||